The role of dust particle counters in clean rooms is crucial. The cleanroom requires the minimum number and particle size of particles in the air to ensure product quality and safety during the production process. The dust particle counter can monitor the number and size of particles in the air in real time, ensuring that the air quality in the clean room always meets the prescribed standards.

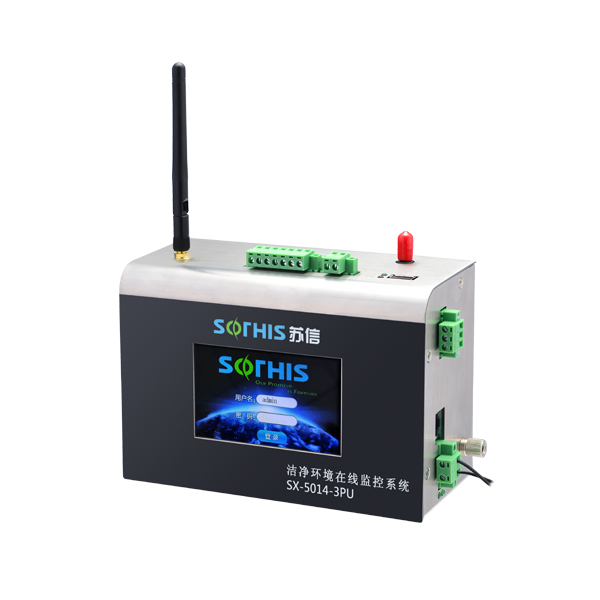

The dust particle counter of Suxin Environment adopts advanced sensing technology, which can accurately detect tiny particles. By monitoring the concentration of particles in the air and adjusting them in real-time according to pre-set standards and thresholds, dust particle counters can help maintain the stability and consistency of the indoor environment in cleanrooms.

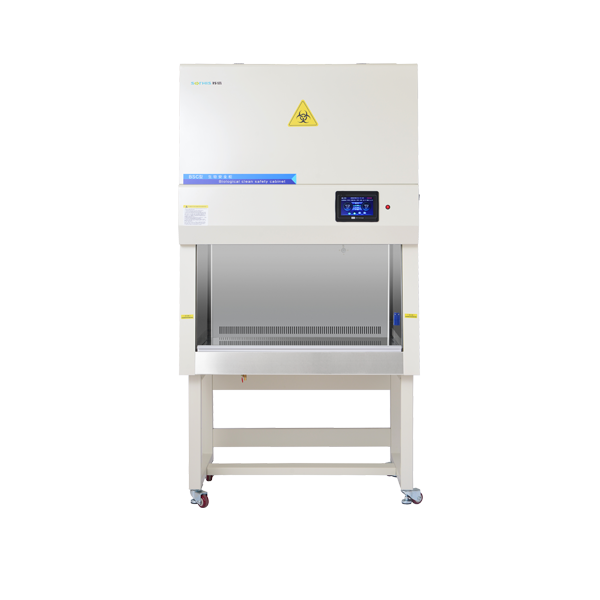

In the pharmaceutical industry, clean rooms are one of the core environments for producing drugs and medical devices. The use of dust particle counters can ensure that the number of particles in the air is below the specified standard, prevent microorganisms or other pollutants from entering the product, and ensure the quality and safety of drugs. Accurate monitoring of dust particle counters is crucial, especially for drug production that requires highly sterile conditions.

In the field of semiconductor manufacturing, a clean room is an essential environment. Tiny dust particles may have a significant impact on chip manufacturing, therefore the air quality requirements for cleanrooms are extremely high. The dust particle counter can monitor and control the number of particles in the air, ensuring cleanliness in the semiconductor production process and improving the success rate and quality of chip production.

Overall, the dust particle counter of Su Xin Environment plays a crucial role in clean rooms. Its high-precision monitoring capability and real-time adjustment function provide reliable assurance for the air quality inside the clean room, ensuring the quality and safety of products during the production process. The application of dust particle counters is driving the development of clean room technology and providing strong support for high-quality production in various fields.