Laser dust particle counter is an instrument used to measure the number and particle size distribution of dust particles per unit volume in clean environments. It can be widely used for clean environment testing in authoritative institutions such as laser dust particle counters, blood centers, epidemic prevention stations, disease control centers, quality supervision institutes, electronics industry, pharmaceutical workshops, semiconductor, optical or pharmaceutical, optical, chemical, food, cosmetics, electronic health, biological products, aerospace, inspection institutes and other production enterprises and scientific research departments

Dust particle counter

Laser dust particle counter is an instrument used to measure the number and particle size distribution of dust particles per unit volume in clean environments. The basic principle is that the detection laser of the optical sensor is scattered by dust particles and received by a photosensitive element to generate a pulse signal. The pulse signal is output and amplified, and then subjected to digital signal processing. By comparing it with the standard particle signal, the comparison result is represented by different parameters.

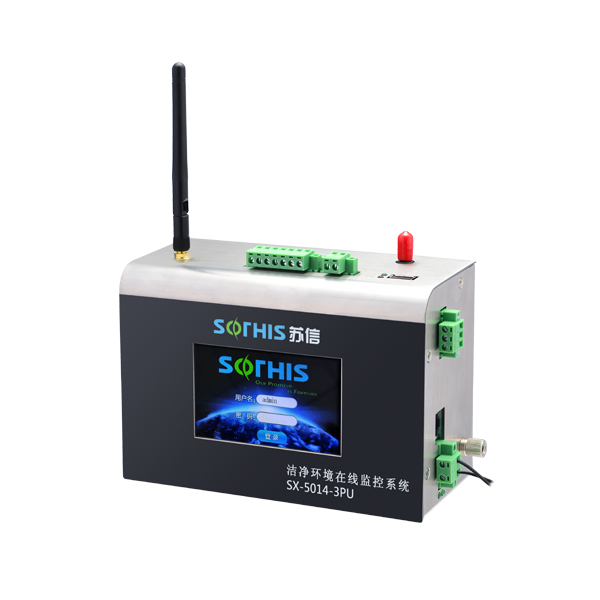

SuXin SX-L301

SuXin SX-L301 laser dust particle counter is a specialized detection instrument for detecting dust particles and cleanroom grades. The technical specifications of this instrument meet the requirements of the "JJF1190-2008 Dust Particle Counter Calibration Specification" issued by the General Administration of Quality Supervision, Inspection and Quarantine of China. This product is widely used in the electronics industry, pharmaceutical industry, food and beverage industry, precision machinery, cosmetics, aerospace industry, scientific research laboratories, environmental protection, various colleges and universities and other production and research units. This instrument is based on the GB50591-2010 "Code for Construction and Acceptance of Cleanrooms" in China. GMP requirements for the pharmaceutical industry. There are six grades of instrument particle size: 0.3, 0.5, 1, 3, 5, and 10 (μ m). The particle size sensitivity of this instrument is maintained at the level of 0.3 μ m, ensuring the accuracy of 0.5 μ m particle size and ensuring the measurement accuracy of cleanliness level 100.

The SuXin SX-L301 series instrument is easy to operate and has a user-friendly human-machine interface. It can conveniently, quickly, and effectively detect suspended particles in purified environments. It is currently the preferred product for pharmaceutical and electronics factories to quickly detect clean room cleanliness. Sensors for measuring temperature and humidity can be configured according to user requirements.

Precautions for use

In daily use and maintenance, the following points should be noted:

1. Do not start the dust particle counter when the inlet pipe is covered or blocked;

2. It should be used in a clean environment to prevent damage to the laser sensor;

3. Do not extract gases containing oil stains or corrosive substances, and do not test mixed gases that may cause reactions (such as hydrogen and oxygen). These gases may also cause explosions inside the counter. If measuring these gases, it is necessary to contact the manufacturer to obtain more information before proceeding with the operation;

4. Do not sample compressed air without high-pressure pressure reducing equipment (such as high-pressure diffusers), all counters are designed to operate at one atmosphere. The working position and sampling port of the instrument should be in the same pressure and temperature and humidity environment to ensure the normal operation of the instrument;

5. Water solution or other liquids cannot enter the sensor through the inlet pipe;

6. The particle counter is mainly used to test the clean environment of the purification workshop. When there are loose particle materials, dust sources, and spray at the tested place, it must be kept at least 12 inches away from the inlet pipe. To prevent contamination of sensors and pipelines by the aforementioned particles and liquids.