Beijing Union Medical Products Co., Ltd. actively implements the strategy of coordinated development between Beijing and Hebei. The Beijing factory is located in the Daxing Biomedical Industry Base of Zhongguancun National Independent Innovation Demonstration Zone, with a construction area of 46000 square meters. Tablets, drop pills, hard capsules, creams, freeze-dried powder injections (anti-tumor drugs) and small volume injections (including anti-tumor drugs) have passed GMP certification. Bicyclol tablets have obtained GMP certification from Ukraine, a member state of the International Convention on Drug Inspection. The Cangzhou branch is located in the Biomedical Industry Park of Bohai New Area, Cangzhou, Beijing. It officially started production of bicyclic alcohol raw materials at the end of 2019.

Recently, Peking Union Medical Products Co., Ltd. ordered 2 weighing rooms from Suzhou Suxin Purification Equipment Factory, which fully proves Peking Union Medical Products Co., Ltd.'s recognition of Suxin products.

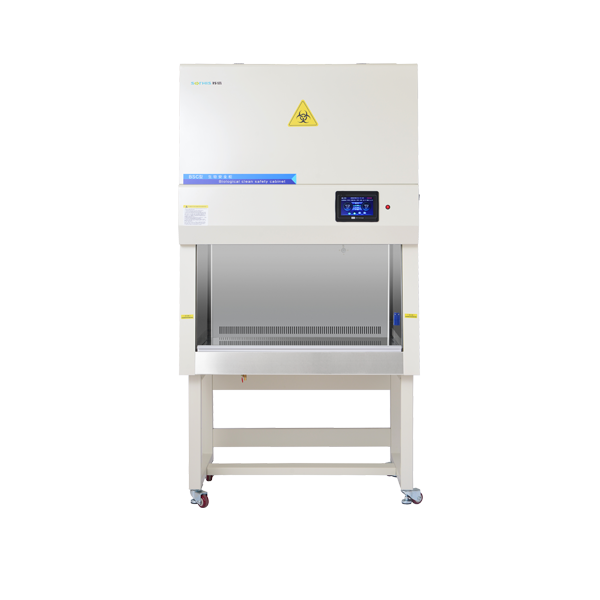

The DB series weighing room is a specialized local purification equipment used in pharmaceutical, microbiological research, and scientific experiments. It is widely used for weighing and measuring raw materials, sampling antibiotics, and processing hormone drugs, whether they are powders or liquids.

The DB series weighing room filters the air through primary and medium efficiency filters, and then presses it into the static pressure box by a centrifugal fan. After passing through the high-efficiency filter, the airflow is diffused to the outlet surface and blown out, forming a vertical unidirectional airflow to protect operators and prevent drug contamination. The operating area of the weighing hood discharges 10% of the circulating air and maintains a negative pressure state to avoid environmental pollution and cross contamination of drugs.

Design reference basis:

1. Pharmaceutical industry standards2. Chinese GMP (2010 version) standard

3. EU GMP standards

4. FDA regulations and the latest CGMP guidelines

The DB series weighing room

| Reference model | Carbon type | Original auxiliary type | ||||||

|

DB- 1100×550 ×950 |

DB-1100×900×2000 | DB-1100×1200×2000 |

DB- 1400×1200 ×2000 |

DB-1700×1300×2000 | DB-1900×1300×2000 | DB-2400×1500×2000 |

DB- 2900×1500 ×2000 |

|

| External dimensions |

1200×750 ×2150 |

1200×1300×2650 | 1200×1600×2650 |

1500×1800 ×2650 |

1800×1900×2650 | 2000×1900×2650 | 2500×2100×2650 |

3000×2100 ×2650 |

| W*H*D(mm) | ||||||||

| Size of workspace |

1100×550 ×950 |

1100×900×2000 | 1100×1200×2000 |

1400×1200 ×2000 |

1700×1300×2000 | 1900×1300×2000 |

2400×1500 ×2000 |

2900×1500 ×2000 |

| W*H*D(mm) | ||||||||

| Cleanliness level | ISO Level 5 (Class 100)/ISO Level 6 (Class 1000) | |||||||

| Primary Filter | G4(90%@5μm) | |||||||

| Medium efficiency filter | F8(85%~95%@1~5μm) | |||||||

| High efficiency filter | H14(99.99%~99.999%@0.5μm) | |||||||

| Average airflow velocity | 0.45±20%m/s | |||||||

| Illuminance | ≥300Lx | |||||||

| Noise | ≤75dB(A) | |||||||

| Power supply | AC 380V/50Hz | |||||||

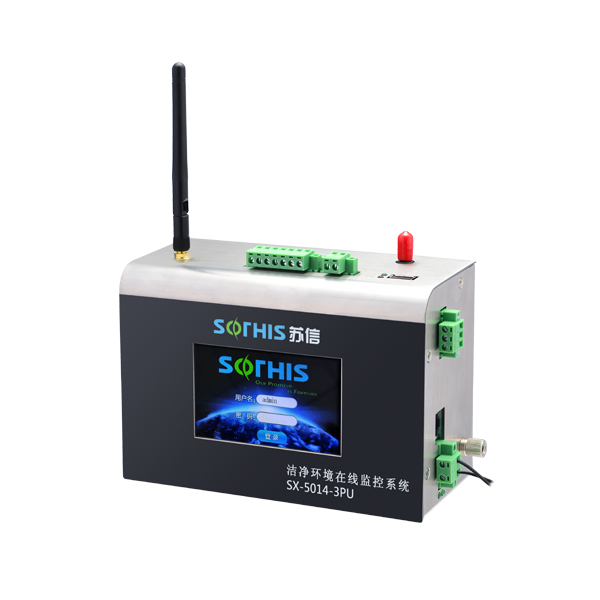

| Control mode | Advanced configuration or basic configuration | |||||||

| Material | SUS 304 T=1.2mm, Magnesium oxide+rock wool fireproof board | |||||||

| Air exhaust | 10% | |||||||

Note: The above dimensions are for reference only and customized non-standard products are accepted