As is well known, the air shower room is an essential purification equipment at the entrance of a clean room. Its main function is to remove dust from the human body through blowing, thereby achieving the purpose of purification. The dust on everyone's body is countless, and the wind blown by the air shower is filtered through two filters, the primary filter and the high-efficiency filter, and then blown onto the person's body. Therefore, as long as the wind force is appropriate, most of the dust on the person's body can be removed. Of course, this is just one of the functions of the air shower room. Another important function of the air shower room is to effectively isolate the outside of the clean room as an effective barrier. The main difference between the air shower room and the buffer room and the airlock room is that the air shower room has a purification, filtration, and blowing function.

argo shower room, as the name suggests, is a specialized air shower room for goods, also known as cargo shower channel or cargo shower door. It is widely used in logistics channels of electronic, food, and packaging enterprises to blow and shower raw materials and tools that are about to enter the clean workshop for operation and processing, achieving the effect of filtering and removing dust particles, and cleaning the raw materials entering the dust-free workshop. Due to the different on-site dimensions of each enterprise's logistics channel and the transportation methods of the raw materials that need to be blown and rained, there is no unified standard for the cargo shower room, and most of them are non-standard products. There are both regular cargo shower rooms and infrared voice prompt cargo shower rooms in terms of functionality, as well as automatic sliding door cargo shower rooms.

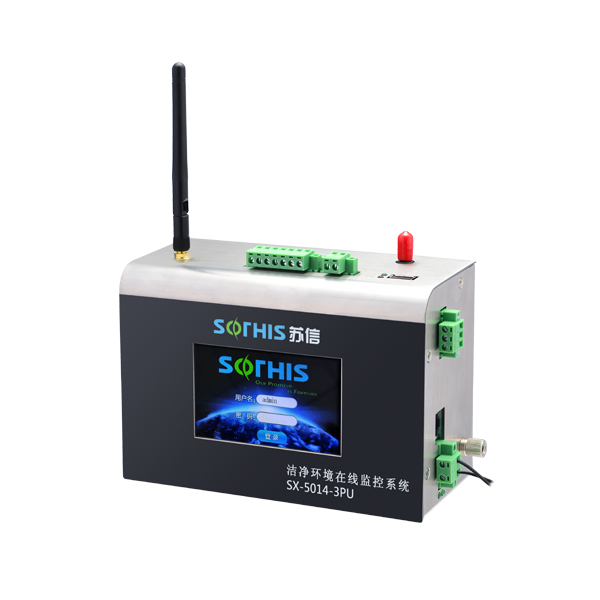

Suxin AAS series air shower room

01 Photoelectric Induction

Photoelectric induction control, implementing automatic spraying, can effectively isolate personnel and dust on the surface of objects from entering the clean room;

02 Safe and Reliable

Advanced intelligent computer control module, low failure, system safety and stability;

03 Easy to operate

LED indicator lights and large screen dynamic control panel design, convenient for dust bath time and operation of various functions;

04 Airflow Design

Airflow circulation design ensures the cleanliness of the air shower area when not in a blowing state;

05 Automatic door lock

Double door electric chain, implementing forced air shower, the two doors can be made into automatic sliding doors or quick rolling shutter doors;

06 On demand design

Personalized design and manufacturing can be carried out according to customer needs (including production of air shower channels, cargo shower channels, explosion-proof air shower rooms, corner air shower rooms; optional materials: high-quality stainless steel, cold-rolled steel plate paint, color steel plate; special design and manufacturing of airlock and buffer types, etc.).

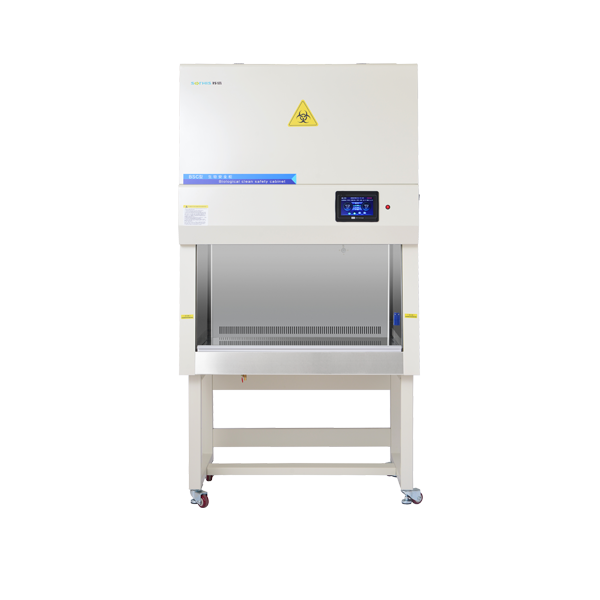

SuXin Environment always provides professional quality and excellent services to customers in different industries, offering comprehensive clean technology solutions for various industries. In addition to the testing instruments, online monitoring, filtration and separation mentioned in the previous article, clean room equipment is also one of the main businesses of SuXin Environment in the company's product line. This includes air shower rooms, cargo shower rooms, clean workbenches, biosafety cabinets, transfer windows FFU、 The customer base of laminar flow hood, weighing platform, high-efficiency air supply outlet, etc. covers multiple industries such as microelectronics, semiconductors, biopharmaceuticals, food and beverage, precision machinery, medical and health care, education and research, new energy, aerospace, etc.