Well, it's normal for lazy people to have such thoughts.

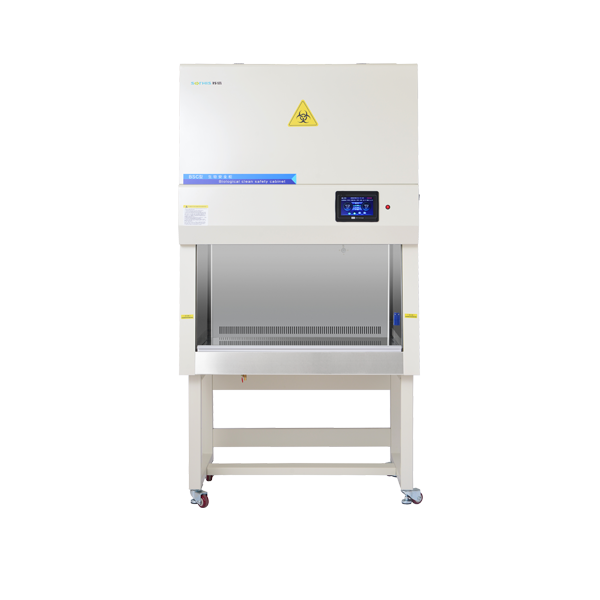

Firstly, let's understand the daily management, monitoring, and control of the cleanroom? Here we take the sterile room as an example.

1. In a sterile room, unless necessary, non essential items are not allowed to enter, which can reduce the probability of contamination of items in the sterile room.

2. All items must have a fixed placement and be returned to their original position after each use.

3. After dry heat sterilization, the items should be placed in an oven or an ultra clean workbench in a sterile room.

4. The shelf life of sterile items is affected by various factors such as temperature, humidity, and sealing. In humid weather and rainy seasons, it is necessary to shorten the storage period.

5. Regular cleaning and disinfection are required.

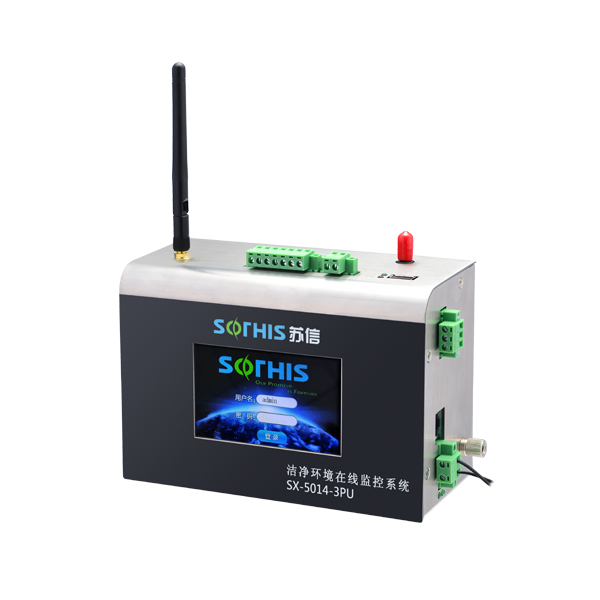

At this point, everyone will be confused. What is the relationship between this and the SX-M cleanliness real-time online monitoring system?

Of course, every daily monitoring and control content is related to the online monitoring system, such as shortening the storage time during rainy seasons, and strengthening monitoring during rainy seasons. Although there is a real-time monitoring system, it is better to be careful, isn't it? A humid environment can lead to microbial growth, and although online systems can monitor data changes at this time, we recommend conducting dual testing. The purpose of real-time monitoring is to ensure that the clean room is in a qualified state at every moment, which compensates for the deficiencies of routine inspections.

But this does not mean that the SX-M cleanliness real-time online monitoring system can replace routine inspections. Routine inspections can also check whether the online system has faults and supervise the system's operation, which can be said to be a dual guarantee.